A simple decision

When professionals think of brakes, the name ATE usually crops up. That’s because we put a lot of thought and experience into the development of our products. Workshops, customers and vehicle manufacturers know exactly why they can totally rely on ATE.

Here’s an example: We use 150 different material compounds for our brake pads and each compound matches the qualities of the series in question. In contrast, our competitors are usually satisfied with between four and five compounds. Anyone who doesn’t want to sacrifice OE quality when replacing wear parts opts for ATE products – it’s as simple as that.

There’s no “sometimes” and “perhaps” at ATE.

When it comes to quality deficits, we are all for the zero solution – and that’s why we set up an ISO 9001-compliant, certified, quality management system in every one of our production facilities. The certification makes high demands on customer orientation, management and other quality criteria. An ongoing process of improvement is also an integral part of the standard.

You can download our aftermarket certificate here:

If it’s a matter of brakes: ATE!

As the specialist for brake systems, ATE has set the benchmarks in quality, innovation and system competence for more than 100 years. Our expertise in research, production and scope of delivery has made us the OEM for the world’s leading automotive suppliers – and the same expertise has made us the aftermarket’s favourite too.

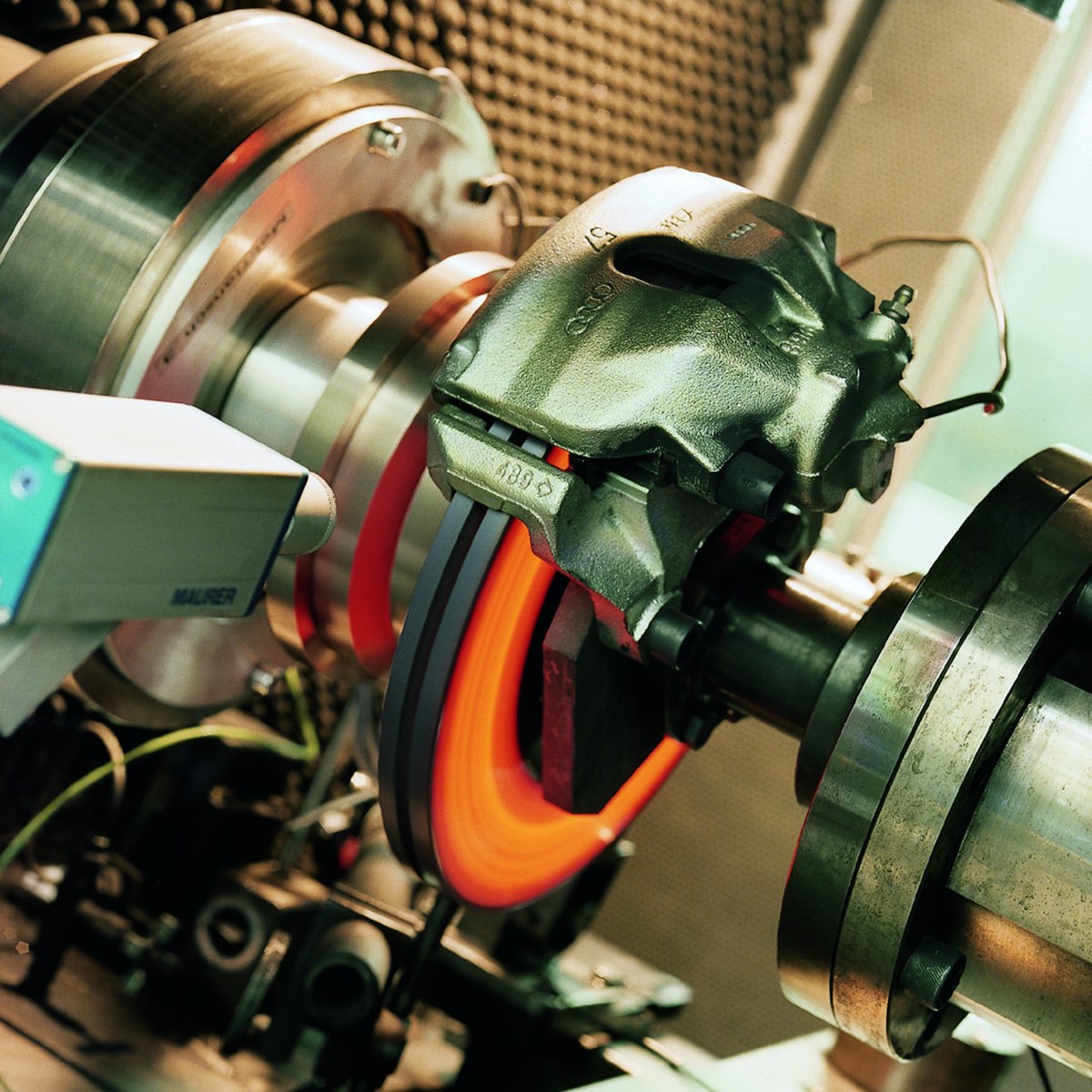

Fully-tested safety – far beyond the (ECE-R90) standard

Consumers deserve the greatest protection and in order to protect them from dangerous, cheap imports, the Economic Commission for Europe (ECE) defined a number of regulations. Brake pads, for example, must pass a series of tests on braking behaviour and friction characteristics before they are given the relevant certificate.

Our internal specifications exceed the standards by far.

We take it one step further

Absolute safety is a must when braking, but that’s not enough for us – more of our voluntary tests cover noise performance and wear on the brake pads and the even thickness of the disc surface (DTV = Disc Thickness Variation). On top of this, our experience in racing flows into series production, allowing car drivers to combine safety with enjoyable driving even under everyday conditions. We strive to create product innovations that constantly target the wishes of the driver.

The basic principles of quality management according to ISO 9001 are:

-

Customer orientation

-

Responsibility in leadership

-

Involvement of the people concerned

-

Process-oriented approach

-

System-oriented approach to management

-

Continuous improvement

-

Fact-based approach to decision-making

-

Mutually beneficial supplier relationships

Brake disc in a load test

Brake disc in a load test

ATE Brake Disc

ATE Ceramic Brake Pad