ATE brake caliper remanufacturing

Good for the environment. Good for your workshop.

The ATE remanufacturing program for brake calipers gives you tried-and-tested OE quality with attractive conditions – it’s fast, reliable and sustainable.

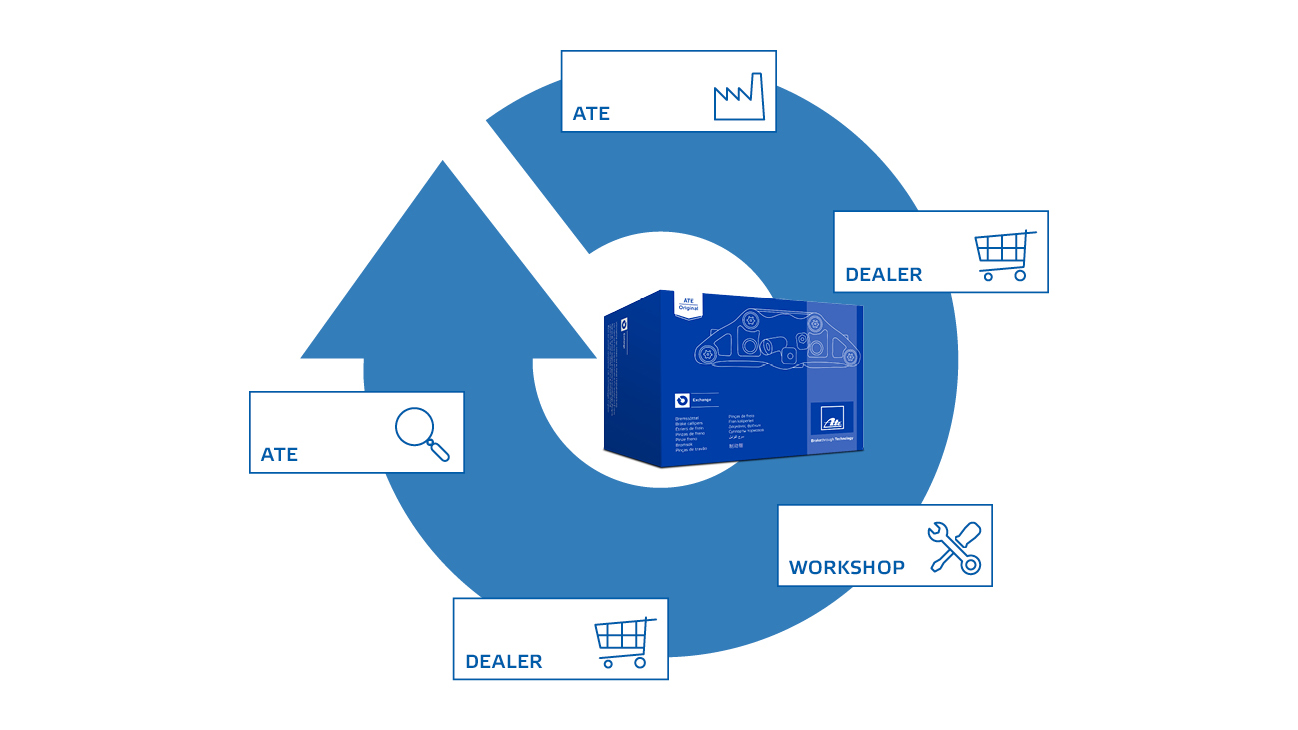

WITH A DEPOSIT SYSTEM FOR THE CLOSED CYCLE PROCESS

Old brake calipers go from your workshop back to the dealer and then on to ATE. At ATE, they are thoroughly inspected, reconditioned and fitted with high-quality original parts. AND you get your deposit back.

CONSERVE RESOURCES – SECURE THE FUTURE

The deposit system ensures that used products are not lost, but flow back into the cycle. This means you’re making an active contribution to environmental protection, because remanufacturing produces a lot less CO2 emissions than a new production process.

YOUR ADVANTAGES AT A GLANCE

- Simple and fast deposit processing

- Brake calipers, as new, in OE quality

- The safety and reliability of new parts

- High availability level – even after series discontinuation

- Sustainable and resource-efficient

RELIABLE MATERIAL FLOW

The deposit system ensures a smooth exchange process between workshops, retailers and ATE. The system ensures a continuous flow of materials – for fast availability, 100 % predictable processes and maximum efficiency in everyday workshop operations.

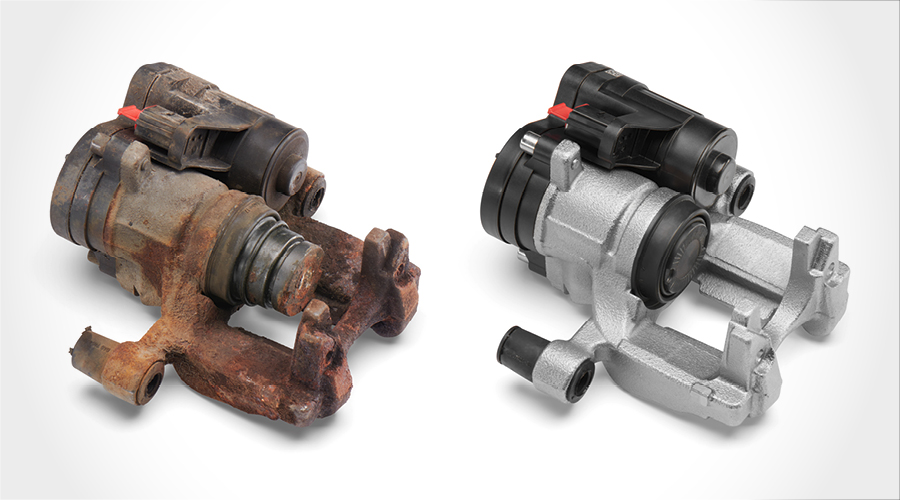

SHEER QUALITY, AS IN THE ORIGINAL EQUIPMENT

Every returned brake caliper is inspected and

remanufactured at ATE according to the strictest criteria:

- Function and material tests (including crack and leak tests)

- Only high-quality ATE seals are used

- High-pressure and safety tests

- Labeling with security tags